Pex NOFP Insulation | Solex Lt Reflective 1/8″ X 4′ X 250′, Perforated

$479.48 $92.00

Pex NOFP Insulation | Solex Lt Reflective 1/8″ X 4′ X 250′, Perforated

Product Description

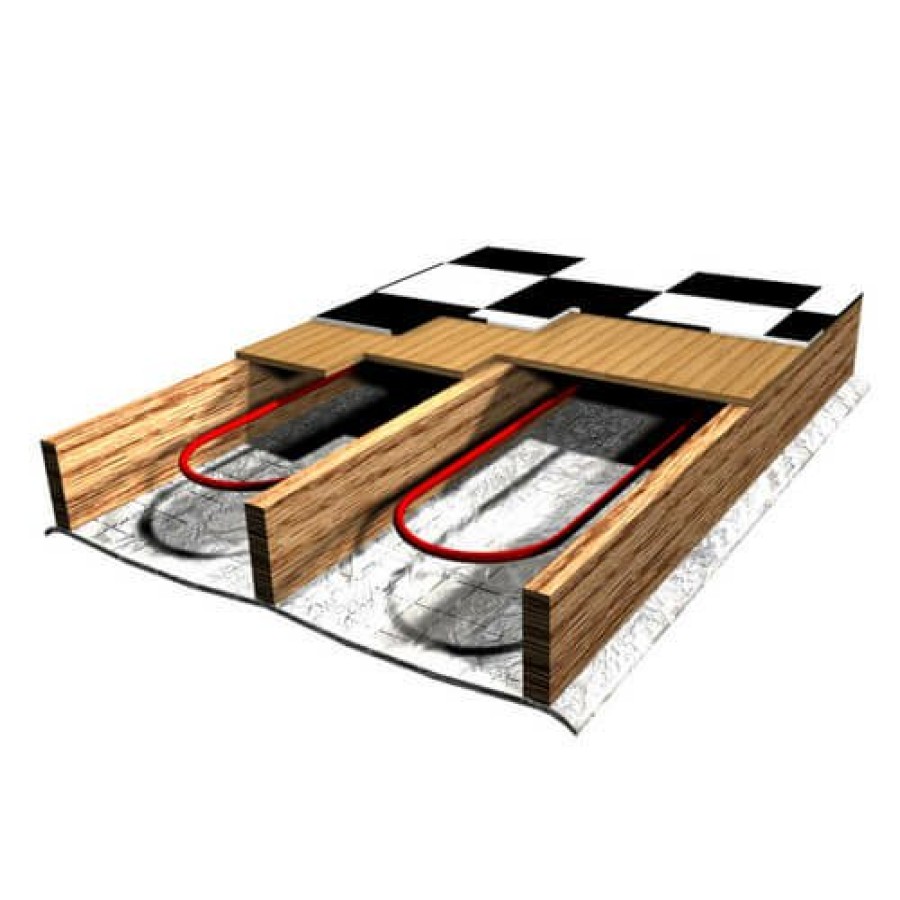

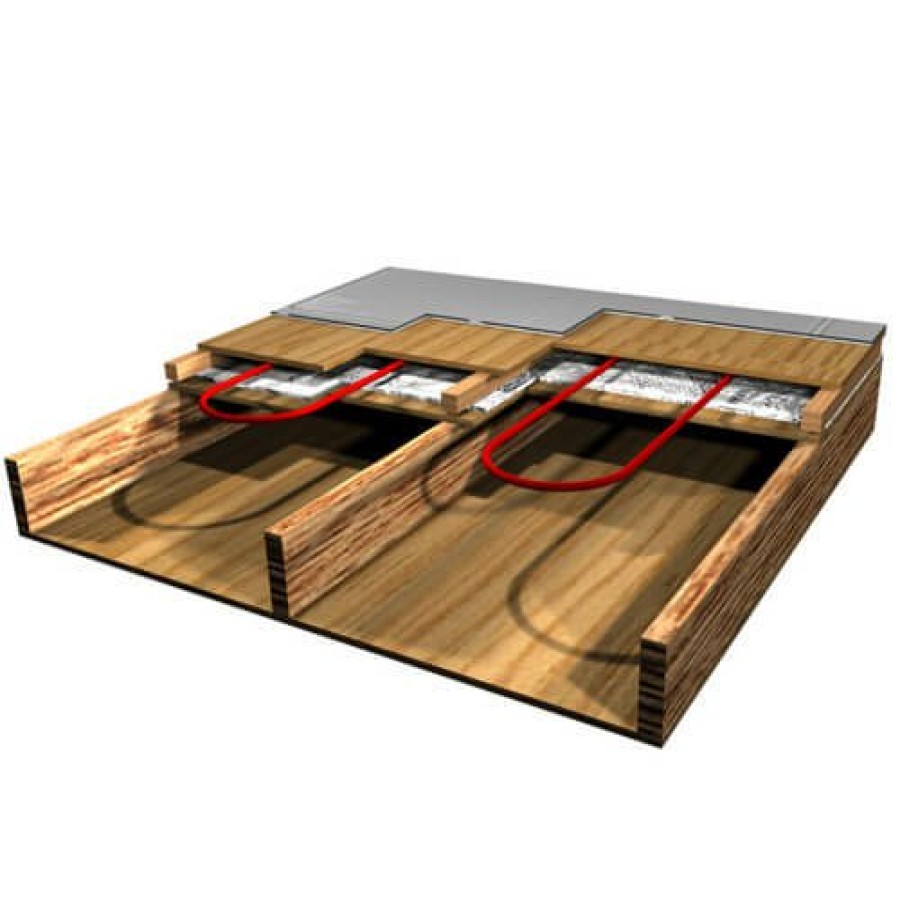

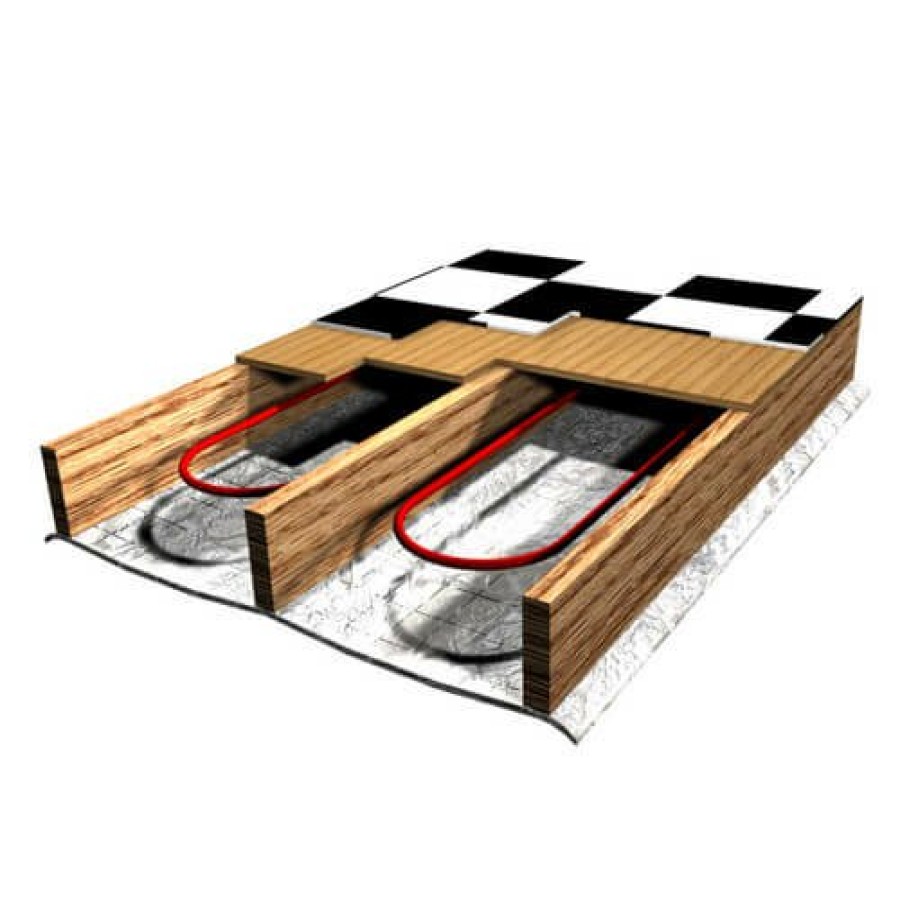

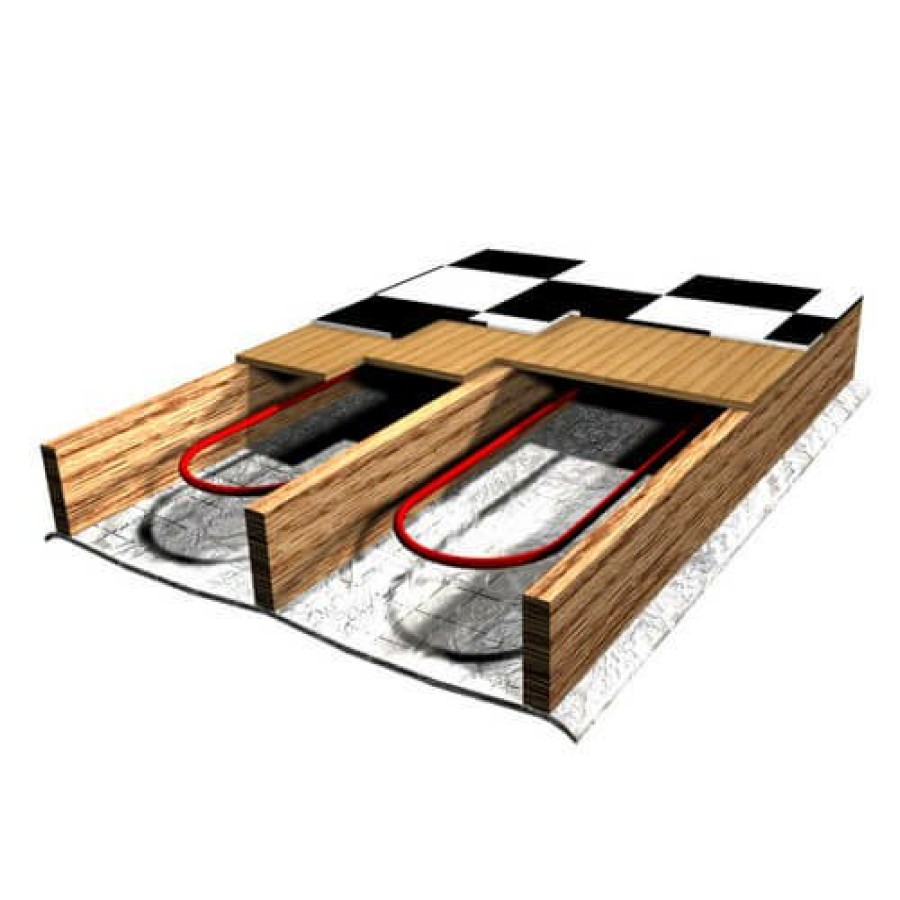

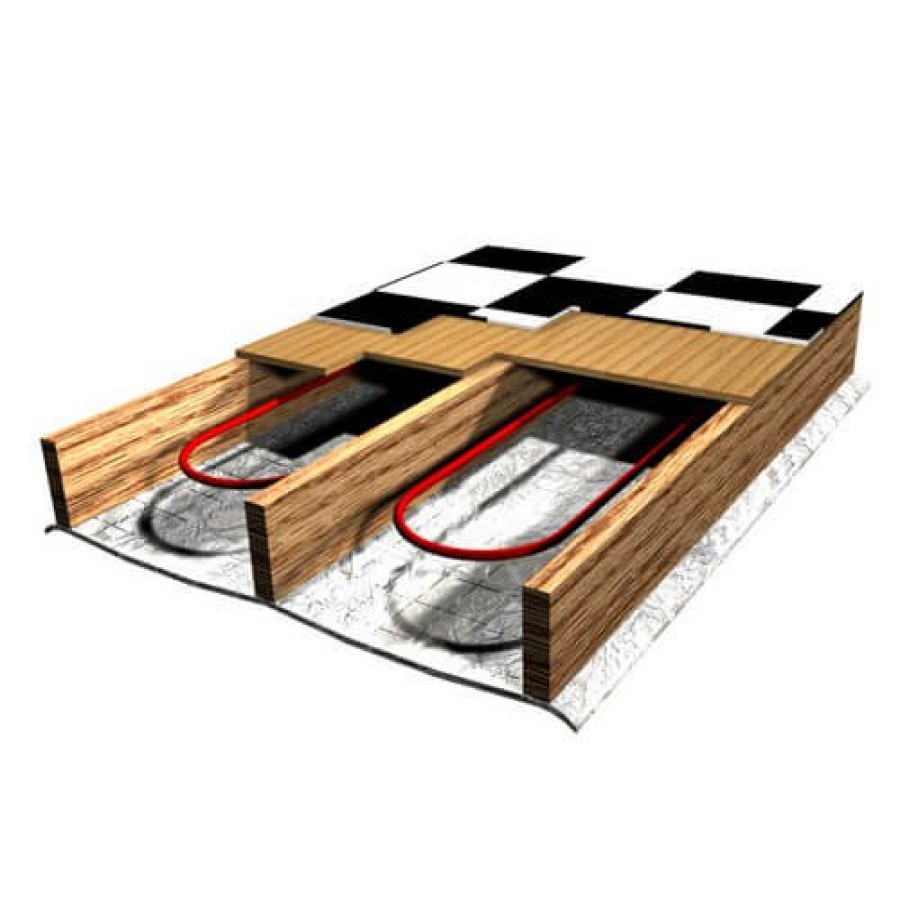

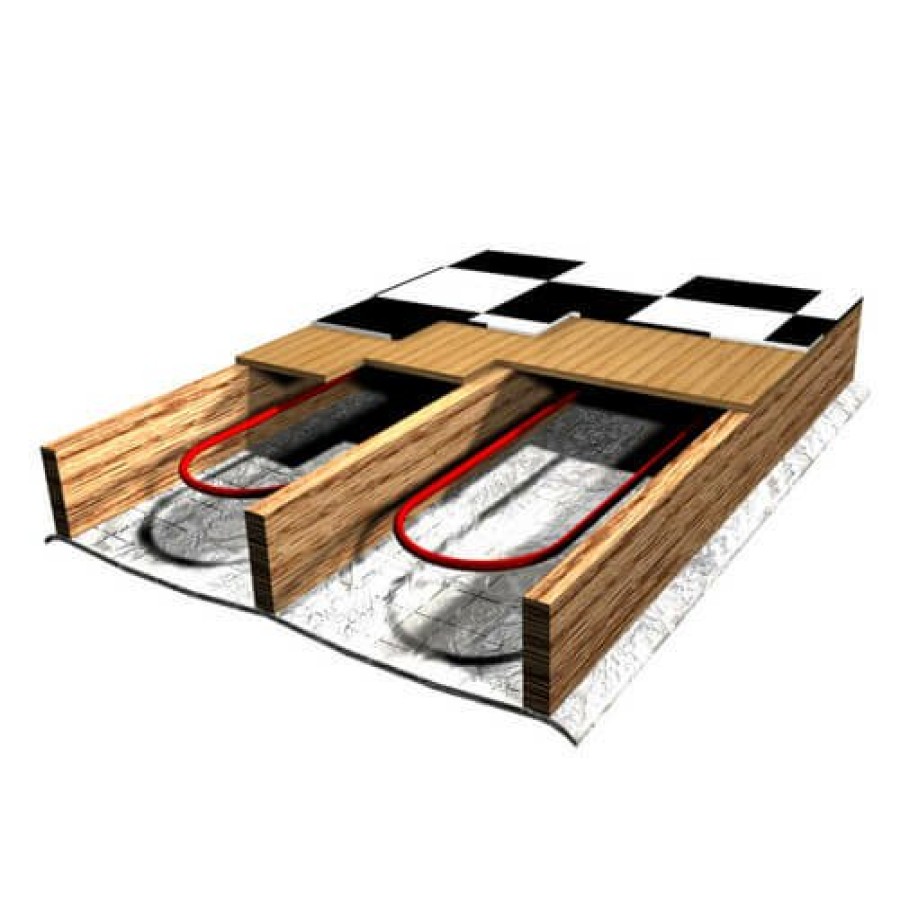

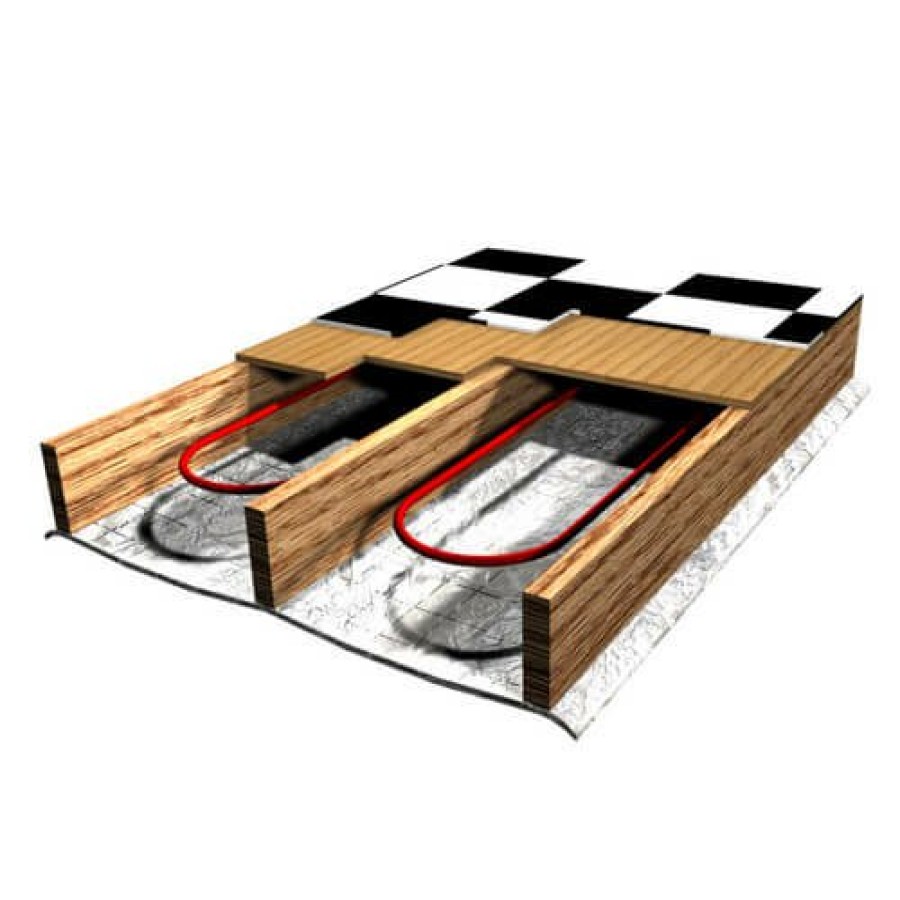

Nofp Solex Reflective Insulation Is Engineered To Increase Energy Efficiency, Provide A Clean Finished Appearance, And Simplify Installation For All Residential, Post Frame, Light-Gauge Steel, And Commercial Insulation Applications. The Core Of The Product Is Made Of A Solid Layer Of Flexible Foam Designed Especially For Nofp That Provides Excellent Insulation Characteristics In A Moisture Proof Design. The Core Of Solexlt Is 1/8″ Thick While Solex Comes Standard At 1/4″ Providing Additional Insulation Value And Durability. In Addition, The Multiple Facing Combinations Are Thermally Bonded In A Unique Process That Provides A Long-Term Quality Finish To Every Solex Roll.

Solexlt: R-Value

- Downwards (7/16″ Osb / 2.75″ Airspace / Solexlt / 2.75′ Airspace / ½” Gypsum)

R-Value 13.1 - Upwards (7/16″ Osb / 2.75″ Airspace / Solexlt / 2.75′ Airspace / ½” Gypsum)

R-Value 7.5 - Horizontal (Vinyl Siding / 1″ Airspace / Solexlt / 7/16″ Osb)

R-Value 5.4 - Horizontal (Vinyl Siding / 2.75″ Airspace / Solexlt / 2.75″ Airspace / ½” Gypsum)

R-Value 9.1

Features & Benefits

- Reflects Up To 97% Of Radiant Energy

- Non-Toxic Lightweight Rolls

- Durable Construction And Long-Lasting Toughness

- Excellent Vapor Barrier

- Multiple Facing Combinations

- Easy Installation With Utility Knife And Tape

- Bird And Insect Resistant

- Increases System Thermal Performance

- Use In Retrofit Or New Construction

Product Use

Solex Products Can Be Used For New Construction As Well As Retrofit In A Variety Of Applications, Such As Post Frame, Horse, Dairy Or Livestock Buildings As Well As For Finished Walls, Building Insulation, Condensation Control, And As A Thermal Break And Vapor Barrier. Solex And Solexlt Can Be Perforated For Applications Where A Vapor Barrier Is Not Needed Such As Behind Siding Or In An Attic.

Reviews

There are no reviews yet.